Robotic Welding Fume Extraction Systems for Wet Collection

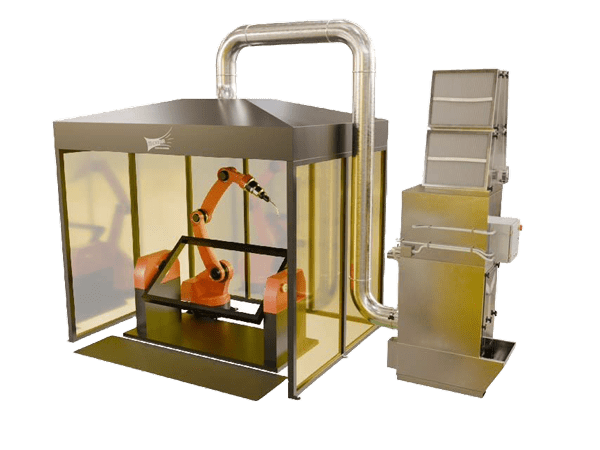

Robotic welding generates intense fumes, fine particulate, and hot sparks that can overwhelm traditional dry-filtration systems—especially in high-production environments. Spartan Air offers wet fume collection systems designed specifically for robotic weld cells, helping you capture weld smoke, reduce fire risk, and return clean air back into the workspace.

If your current system is triggering shutdowns, causing filter issues, or creating ongoing safety concerns, wet collection is often the safest and most reliable solution for robotic welding applications.

Why Robotic Weld Cells Require a Different Approach

Robotic welding isn’t a “standard” fume application. Compared to manual welding, robotic cells produce consistent, high-volume smoke and particulate emissions, often accompanied by spatters and embers that increase the risk of fires in dry collectors. Wet collection systems are designed to address this reality—cooling and extinguishing embers before they reach the filtration stages.

These systems are built to:

- Support cleaner, safer working conditions

- Capture weld fume at the source

- Reduce combustible dust and fire hazards

- Improve uptime and reliability

How Wet Fume Collection Works for Robotic Welding

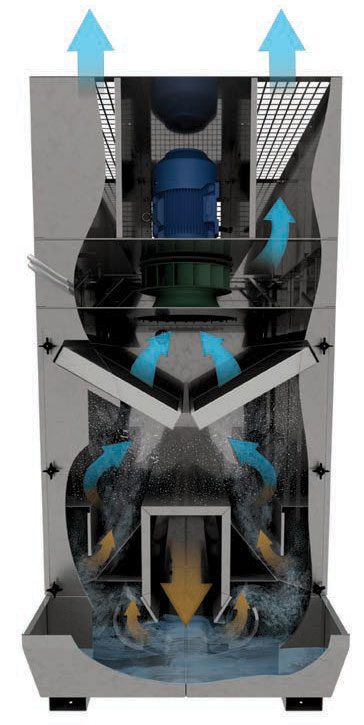

Dirty air is pulled from the weld cell through ducting and enters the wet collector. Inside the unit, contaminated air is mixed into a turbulent water bath and directed through engineered internal baffles. The combination of water agitation and baffle design helps extinguish welding—generated embers, significantly reducing the risk of fire compared to dry cartridge-style systems.

Collected particulate is contained at the bottom of the unit for safe removal. Moisture-laden air is then routed through a high-efficiency chevron-style de-misting filter. Final filtration is completed using a MERV 16 after-filter, helping ensure cleaner air is returned to the workspace.

NFPA 660 Compliant Robotic Weld Cell Collection

For operations involving combustible particulate and sparks, system design and code compliance are critical. These wet collectors are designed for robotic welding applications and are NFPA 660 compliant, providing an additional layer of safety for safety-focused facilities.

Available Configurations

Spartan Air can provide wet robotic welding collection systems in multiple configurations to fit different cell layouts and airflow requirements:

- 2,500 CFM Ducted Configuration

- 5,000 CFM Ducted Configuration

- 5,000 CFM Direct Coupled Configuration The direct-coupled option includes a slotted inlet hood for high-efficiency capture where ductwork is limited or space is tight.

Standard Features Designed for Safety and Reliability

Wet robotic weld collection systems include a wide range of built-in controls and safety functionality to help protect your facility and maintain consistent performance:

Safety & Interlocks

Safety & Interlocks

- Low sump water level interlock for weld equipment shutdown

- Interlock to monitor fume/smoke-producing equipment

- After-filter high-temperature monitoring and shutdown

- Automatic sump water level control (capacitance sensors)

- UL-listed controls and NEMA 4 control panel

- Non-fused rotary disconnect switch

- High sump level shutdown

- Powered off-gas damper

Performance & Efficiency

Performance & Efficiency

- Integrated VFD to maintain steady airflow across the life of the after-filter

- Non-sparking direct drive blower

- Full 304 stainless steel construction

- Remote start/stop functionality for weld controller integration

- High-efficiency MERV 16 rinseable, fire-resistant after-filters with filter monitoring

Specifications (System Summary)

Specifications (System Summary)

Key specifications include:

- Air Volume: 2,500 CFM or 5,000 CFM

- Motor:

- 2,500 CFM model: 7.5 HP TEFC, 230/460V, 3-phase

- 5,000 CFM model: 15 HP TEFC, 230/460V, 3-phase

- Blower: Aluminum, non-sparking, direct drive

- Cabinet: Heavy-duty welded 304 stainless steel (16 ga with 12 ga structural components)

- Inlet: Rear inlet collar (10” for 2,500 CFM, 14” for 5,000 CFM)

- After-Filter: Rinseable MERV 16 after-filters in A-frame exhaust outlet

- Filter Access: Quick front/door access for de-misting and after-filters

- Sump Vent: 4” electronically controlled vent with off-gas collar

A Case Study with Proven Results: Eliminating Fire Hazards in Robotic Weld Cells

In a real-world case study, a Tier 1 just-in-time automotive supplier was experiencing frequent and hazardous fires in an existing competitor-supplied collection system. The fires triggered full factory evacuations, halted production lines, and caused delayed deliveries—creating significant financial penalties and operational losses.

After switching to wet collection using the WC2500 system with VFDs and after-filters, the client reported a major reduction in risk and a measurable improvement in reliability and plant safety, including:

- No fire-related production stoppages

- No evacuations

- No delivery delays linked to collector fires

The result was a major reduction in risk and a measurable improvement in reliability and plant safety.

Spartan Air Can Help You Design the Right Robotic Welding System

Every robotic cell is different. Duct runs, robot cell enclosure design, welding type, duty cycle, and airflow requirements all matter. Spartan Air works with you to engineer the right wet collection solution based on:

- Number of weld cells

- Required airflow and capture points

- Ducted vs direct-coupled configuration needs

- Safety and fire risk considerations

- Maintenance and service preferences

If you’re planning a new robotic cell—or troubleshooting a problem with fires, clogging, or unreliable filtration—our team can help you select a safer, more stable approach.

Request a Quote or System Review

Want to know if wet collection is the right solution for your robotic welding application? Spartan Air can review your weld cell setup, airflow needs, and safety requirements to recommend the best configuration.

Contact Spartan Air today to discuss robotic welding fume extraction systems.